| Buttweld pipe fittings : |

Buttweld pipe fittings of 45, 90, 180, L.R./ S.R Elbows, Equal/Unequal Tees, Barred tees, Reducers, stubends, caps, cross, short radius Bends up to size 32" N.B., 800 MM N.B.We are specialist of Pipe Fittings in Monel, Inconel, Coupro Nickel, Titanium,904L, Duplex, Aluminium, Hastalloy, Alloy20,L,T,C,S.,Alloy Steel,P11,P22,P5 & P9, P91. |

Long radius Piggable Bends : |

Seamless & Welded long radius piggable bends in 2D, 5D, 8D upto 22D, 45,90,180,360 sizes upto 24" N.B.half and full size rings and spray ring headers upto 7000 mm dia. Also manufacture 'J'. 'S', ' U' and special bends,tangents lengthas per requirement.Oval rings, spool pieces etc.as per customer drawing & specification.For L.R. Bends dimension, Flattening on any point max.1.7% ovality within 1% of the Diameter of pipe, Deg.+/- 1.5, Thinning max.5% of W.T., No flaring, wrinkle free bends, dummy pig pass test done with 96.5% ID of bend. |

|

| Material of Construction |

| MATERIAL |

SIZE (MM) |

SCH. |

THICKNESS |

SPECN. |

METHOD |

| STAINLESS STEEL |

15 NB to 250 NB

40 NB to 800 NB |

5S to XXS

5S to 80S |

1.65 to 22 mm

1.65 to 25 mm |

A 403

A 403 |

SEAMLESS

WELDED |

| ALLOY STEEL |

50 NB to 500 NB

300 NB to 800 NB |

40 to XXS

10, 20, 30, 40, 80 |

3.91 to 30 mm

6.35 to 36 mm |

A 234 WP

A 234 WP |

SEAMLESS WELDED |

| CARBON STEEL |

50 NB to 500 NB

200 NB to 800 NB |

40 to XXS

10, 20, 30, 40, 80 |

3.91 to 40 mm

6.35 to 45 mm |

A 234 WPB

A 234 WPB |

SEAMLESS WELDED |

LOW TEMP

CARBON STEEL |

25 NB to 400 NB

200 NB to 800 NB |

10, 20, 30, 40, 80

10, 20, 30, 40, 80 |

3.91 to 30 mm

6.35 to 40 mm |

A 420 WPL

A 420 WPL |

SEAMLESS WELDED |

CUPRO-NICKEL,

MONEL,TITANIUM, |

15 NB to 250 NB

40 NB to 800 NB

1/2" to 8" OD |

5S to XXS

5S to 80S

22 SWG to 6 SWG |

1.65 to 22 mm

1.65 to 25 mm

0.80 to 22 mm |

ASME,

ASTM,

BS, DIN, |

SEAMLESS WELDED |

ALUMINIUM

INCONEL,

HASTALLOY &

UNS DESIGNATION |

15 NB to 250 NB

40 NB to 800 NB

1/2" to 8" OD |

5S to XXS

5S to 80S

22 SWG to 6 SWG |

1.65 to 22 mm

1.65 to 25 mm

0.80 to 22 mm |

ASME,

ASTM,

BS, DIN, |

SEAMLESS WELDED |

| We also Supply |

SS/AS/CS/LTCS

CU/NI/AL/TI |

15 NB to 80 NB |

3000, 6000,

9000 # |

SOCKET WELD |

A182/A105

ASTM/BS |

FORGED |

SS/AS/CS/LTCS

CU/NI/AL/TI |

15 NB to 80 NB |

150, 300, 600,

900# |

WN, SORF,

BLRF |

A182/A105

ASME/ DIN |

FORGED |

ASTM A234/234M PIPE FITTINGS OF WROUGHT CARBON STEEL FOR

MODERATE AND ELEVATED TEMPERATURE |

ASTM

Grade |

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Mo |

Other |

Tensile

Psi(MPa) |

Yield

Psi(MPa) |

Elongation

% |

Hardness

HB |

| A234 WPB |

0.30

max. |

0.29

1.06 |

0.10

min. |

0.058

max |

0.050

max |

|

|

|

|

60000-85000

(415-585) |

35000

(240) |

30Recp.Spc.

22Round Spc. |

197 |

A234/234M

WP11CL-1 |

0.15 |

0.30

0.60 |

0.50

1.00 |

0.030

max |

0.030

max |

1.00

1.50 |

|

0.44

0.65 |

|

60000-85000

(415-585) |

30000

(205) |

30Recp.Spc.

22Round Spc. |

197 |

A234/234M

WP 5 |

0.15

max |

0.30

0.60 |

0.50

max |

0.030

max |

0.040

max |

40..

6.00 |

|

0.44

0.65 |

|

60000-85000

(415-585) |

30000

(205) |

30Recp.Spc.

22Round Spc. |

217 |

A403/403M

WP304L |

0.035

max |

2.00 |

1.00

|

0.030 |

0.045 |

18.00

20.00 |

8.00

13.00 |

|

|

70000

(485) |

25000

(170) |

28(Longit)

20(Transv.) |

|

A403/403M

WP310 |

0.015

max |

2.00 |

1.50 |

0.030 |

0.045 |

24.00

26.00 |

19.00

22.00 |

|

|

75000

(485) |

30000

(205) |

28(Longit)

20(Transv.) |

|

A403/403M

WP316L |

0.035

max |

2.00 |

1.00 |

0.030 |

0.045 |

16.00

18.00 |

10.00

15.00 |

2.00

3.00 |

|

70000

(485) |

25000

(170) |

28(Longit)

20(Transv.) |

|

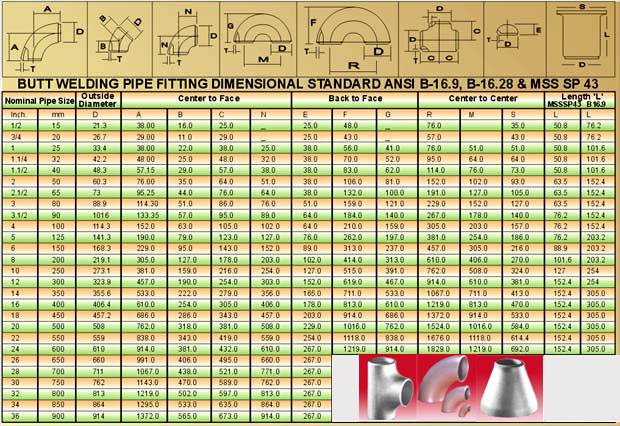

BUTT WELDING PIPE FITTING DIMENSIONAL STANDARD ANSI B-16.9, B-16.28 & MSS SP 43

Click here for Larger View

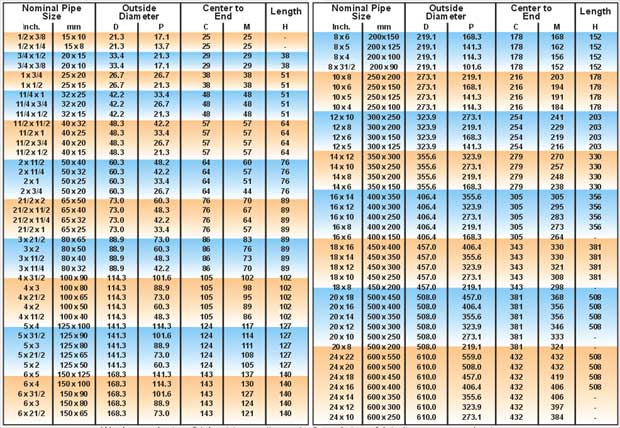

BUTT-WELDING PIPE FITTINGS ANSI B 16.9 AND B 16.28

Click here for Larger View

We also supply pipes & take piping erection contracts & spool pieces fabrication as per your drawing

SPECIAL PRODUCTS MANUFACTURED

|

|

Long Radius Piggable Bends |

|

|

R=3D, 5D, 8D... 22D & Size Upto 32" |

Long Radius Bends Piggable And Pressure Vessel Use

In stainless steel, alloy steel, carbon steel & nickel alloys seamless & welded long radius piggable bends half and full size rings and spray ring headers upto 7000 mm dia. mfg. range:- 2d, 5d, 8d, upto 22d, 45o, 90o, 180o, 360o sizes upto 24 " nb also mfg. "j", "s", "u" and special bends, oval rings, spool pieces etc. as per customer drawing & specn. |

DIMENSIONAL TOLERANCE :

flattening on any point max. 1.7% ovality within 1.5% of the dia. of pipe angle +/- 1.5o of w.t., thinning max. 5.9% of w.t., dummy pig pass test done with 96% i.d.

of bends, no flaring, wrinkle free bends |

WE ALSO MANUFACTURE |

Large Size Butt Weld Pipe Fittings Up to 32" N.B. |

MANUFACTURING PROCEDURE FOR LONG RADIUS PIGGABLE BENDS |

Stainless Steel, Alloy Steel, Carbon Steel, L.T.C.S., NACE & NICKEL ALLOYS |

Seamless & Welded Long Radius Piggable Bends & Spray Ring Headers Mfg.

Range : 2D, 5D, 8D Upto 22D, 45°, 90°, 180°, 360° size upto 24"NB |

Dimension Tolerances : Flattening on any point max 2.2%, Angle +/- 1.5° ovality with in 1.5% of the Dia.of pipe,thinning max.5.9% of W.T.,Wrinkle free Bends. Dummy pig test shall be done upto 96% I.D.of Bend |

1. ISSUE OF WORK ORDER :

1.1 Technically & commercially clear Purchase Order.

1.2 Manufacturing Codes / Standards as per Client Requirement / Approved Drawing/Approved QAP.

1.3 Technical Data like Matrl Spec, & Dimn, NDT Requirement & its Specn

1.4 For free issued Pipes by client, we take proper care for handling, secure storing, saving minimum wastage, proper accounting and its after Mfrg. For bend physical properties are being maintained, as per M.T.C. of pipe, with any third party inspection agency.

2. RAW MATERIAL RECEPT, INSPECTION & ACCEPTANCE:-

2.1 Verification of purchased material as per Purchase Order and Specn.

2.2 Co-Relation of Heat No of Material with Mill Test Cert.

2.3 Co-Relation of MTC as per Spen.

2.4 For all accepted materials Visual and dimensional check are carried out.

2.5 Punching Lot Nos and Color-coding using hard punch/ Stencil allotted identification No. For materials.

2.6 If original MTC is not received / available check testing is carried out

3. MANUFACTURING CONTROL OF SEAMLESS & WELDED LONG RADIUS PIPE BENDS:-

3.1 Marking on pipes are done as per Cutting Length make sure the individual pieces

bears the Allotted Lot No.

3.2 The pipes are filled with sand, lead or Gum based Rosin.

3.3 After filling of Insert Material the pipes are taken for further Hot/Cold forming process.

3.4 Stage wise Inspection is carried out on Processing Level Like Flattening, ovality, thinning, Wrinkle & Angle.

3.5 If any type welding is required for bends, our welders are qualified as per your approved WPS & PQR.

3.6 Final Inspection is carried out on bending machine, before taken out for final processing.

3.7 Visual and Dimension check are carried out during production for Flattening radius Diameter / Ovality, Height Bevel end angle, Min. & Max. Wall thickness is Recorded. NDT is carried out as per Approved QAP/DRG.

3.8 Heat Treatment:- For S.S. solution annealing, A.S. annealing, C.S. normalizing L.T.C.S hardenng & temper.

3.9 Test coupon are send for check testing as per specification / Approved QAP/DRG./ Client Requirement.

3.10 For S.S. Bends pickling, and passivation are carried out before dispatch.

3.11 C.S., A.S. & L.T.C.S bends are shot blasted, wire brushed and rust preventives are applied before dispatch.

3.12 Final marking are done by Hard Punching/Stencile that bears the following details

(Mfg's Monogram / Specn/Dimn/Size/Sch/Ht-Lot No) and any other details.

3.13 All Relevant documents are prepared Dimensional Reports, Inspection reports,

NDT Reports, Mfg. Test Certif.

3.14 After the records are completed bends are offered to Client or Third Party agency for inspection.

3.15 After Inspection, acceptance and final stamping by inspection agency. The item is released to store.

3.16 After getting the internal / shipping clearance note the Stores will pack the items with suitable packing material, as Per spec, with packing lists, to avoid any kind of damage during Transit. |

|

|

|

Contact Us :: Contact Us ::

Champak Steel & Engg. Co.

390/392 Shankar Mansion, S.V.P. Road, Mumbai - 400004.

Contact Person: Mr. Vimal Jain

Email:

Tel: +91-22-66159016 / 66159001

Fax:+91-22-66159023

|

|

|