NSSMC STOCKIEST. Abrex 400, Abrex 450, Abrex 500, Abrex 600 Stockists & Suppliers

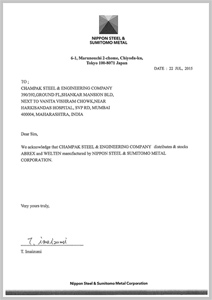

NIPPON STEEL & SUMITOMO METAL CORPORATION STOCKIST

NSSMC JAPAN ABREX & WELTEN STEEL BUYER.

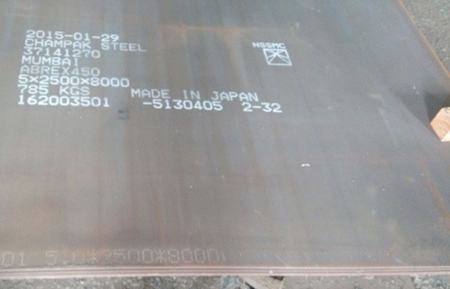

Champak Steel & Engg. Company stocks ABREX ans WELTEN Plate manufactured by Nippon steel & Sumitomo Metal Corporation, Japan.

Champak Steel & Engg. Company stocks ABREX ans WELTEN Plate manufactured by Nippon steel & Sumitomo Metal Corporation, Japan.

The use of abrasion resistance ABREX steel plate markedly reduces the weight of structural members exposed to serve abrasive conditions. Compare with regular steel, ABREX steel plate reduces structural weight and delivers economic merits.

Adoption of high performance abrasion resistant ABREX will prolong the service life of machinery and component.

Thickness : 3mm to 100mm THK

Send Online Enquiry

Abrex Plate Applications :

- Dump Truck Liners

- Cutting Edges

- Drag line Bucket Wear Liners

- Screen Plates - Chute Liners

- Conveyor Buckets

- Hoppers

- Ore Scrapers

Certificate

|

|

NIPPON STEEL & SUMITOMO METAL CORPORATION STOCKIEST

|

NSSMC STOCKIEST. Abrex 400, Abrex 450, Abrex 500, Abrex 600 Stockists & Suppliers

NIPPON STEEL & SUMITOMO METAL CORPORATION STOCKIEST

NSSMC JAPAN ABREX & WELTEN STEEL BUYER.

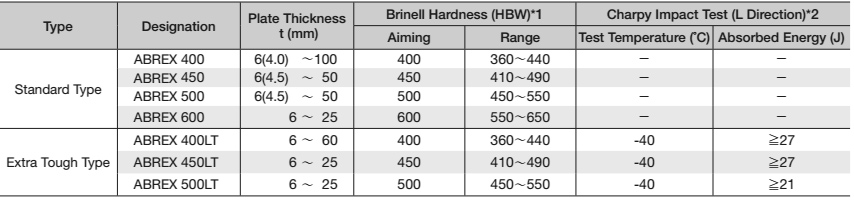

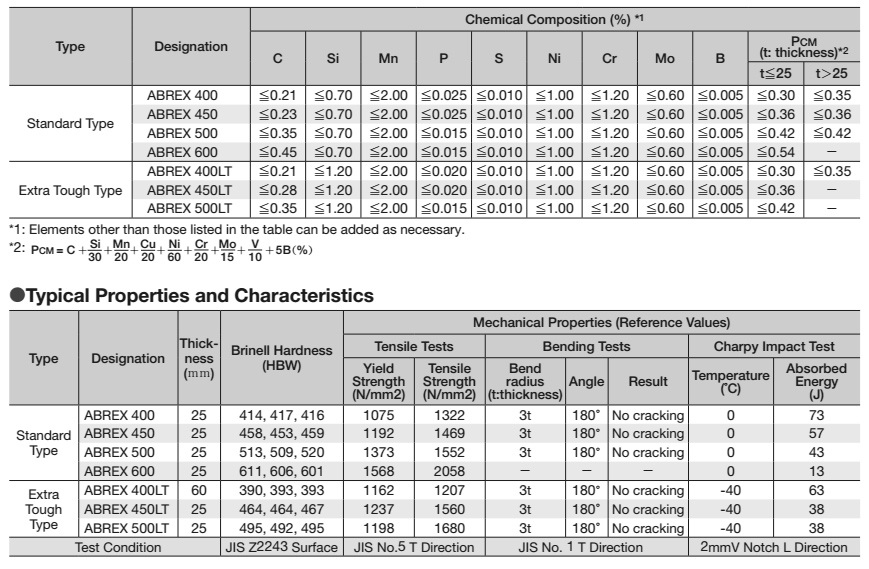

Specifications by Type and Designation

1. The Brinell Hardness Value is an avarage of measurements taken from three points on the steel plate surface. A section of the surface from which the decarburized layer is ground off by about 0.7mm should be used as the specimen surface. Prior counsultation is recommended in the case of using thicknesses surpassing those listed above.

2. The Charpy Impact Test shall be applied to steel plates thicker than 12mm.

Increasing the thickness of the steel plate will lead to slight decrease in the hardness of the central portion of the plate. In the event that these steel plates need to perform at high tempratures, please cousult with us prior to placing your order. In the event that these steel plates need to perform at low temperatures, please select the Extra Tough Steel Plate options.

Abrex Steel Plate Excellent Abrasion Resistant 4 or 5 times stronger than ordinary steel Excellent Workability Larger in elongation and better in workability Excellent Weldability Decrease deformation rate Wide range of sizes Available in a wide range of sizes.

GRADE 400 / 500

| Thickness |

Width |

Length |

| 4 |

2000 |

6000 |

| 5 |

2000 |

6000 |

| 6 |

2000 |

6000 |

| 6 |

2500 |

6000 |

| 8 |

2000 |

6000 |

| 8 |

2500 |

6000 |

| 10 |

2000 |

6000 |

| 12 |

2000 |

6000 |

| 15 |

2000 |

6000 |

| 16 |

2000 |

6000 |

| 20 |

2000 |

6000 |

| 25 |

2000 |

6000 |

| 32 |

2000 |

6000 |

| 40 |

2000 |

6000 |

| 50 |

2000 |

6000 |

| 60 |

1800 |

3400 |

Brand |

Manufacture/Co |

HARDNESS RANGE

Values for AR 400 |

C.E.V. Typical Values

Thk: 10 – 20 |

| Abrex 400 |

NSSMC |

360-440 |

0.40 |

| Abrex 450 |

NSSMC |

410-490 |

0.50 |

| Abrex 500 |

NSSMC |

450-550 |

0.55 |

| Abrex 600 |

NSSMC |

550-650 |

0.73 |

Fabrication of Abrasion Resistant Steel :

Welding :

Abrazo 400 can be welded under normal conditions (if you require advice on welding, machining or forming then please contact any one of our offices) using MMA, MOG and SAW without preheat, up to a combined thickness of 60mm, provided hydrogen controlled electrodes are used. Consumables should be dried in accordance with scale ‘D’ of BS 5135. Consumables should be chosen on the basis of whether or not the weld metal is exposed to wear conditions.

Machining :

Machining or drilling is more difficult due to hardness. For 400BHN use high-grade cobalt HSS E drilling tools and for 500BHN hard metal drilling tools are necessary.

Forming :

Abrasion steels can be readily cold formed. Compared with steels of lower yields, three factors should be considered:

- Higher press forces

- A greater bend radius is required

- Spring back.

Flame Cutting :

Material can be cut using conventional flame cutting practices without the need for preheat at ambient temperature. The following cutting parameters are recommended:-

Plate

Thickness

(mm) |

Nozzle

Size

(LPN mm) |

Cutting O2

(Lb.in2) |

Heating O2

(Lb.in2) |

Heating

propane

(Lb.in2) |

Cutting

speed

(mm/min) |

CEV

max

% |

| 12.5 |

10-25 |

45 |

40 |

18 |

450 |

0.40 |

| 15.0 |

10-25 |

50 |

40 |

10 |

490 |

0.40 |

| 25.0 |

25-40 |

60 |

40 |

20 |

400 |

0.52 |

| 40.0 |

40-60 |

70 |

40 |

10 |

310 |

0.52 |

| 50.0 |

40-60 |

75 |

40 |

10 |

300 |

0.57 |

| 65-80 |

60-100 |

71 |

31 |

13 |

239 |

0.57 |

Milling :

Abrasion resistant steel can be machined by milling.

The following recommendations are given for general guidance:-

| Steel Grade |

Cutting Speed (mm/min) |

Feed (mm/tooth) |

Abrazo 400* |

100 |

0.10-0.15 |

* For further information on 450, 500 please contact us for details.

Cold Bending :

Where possible, cold bending should be carried out with the bend axis perpendicular to the rolling direction, this being the less onerous of the two directions. The following table contains guidelines for bending to a 90°angle. In general however, bending radii should be as generous as possible.

| Bending direction (bend axis) |

Minimum inside

Bending radius |

Minimum die

opening |

Perpendicular to rolling direction |

3t |

8.5t |

Parallel to rolling direction |

4t |

10t |

Abrex Plate Company, Abrex 400, Abrex 450, Abrex 500, Abrex 600 Stockiests & Suppliers, Abrex Plate Wholesaler, Abrex Plate Wholesale, Abrex Plate Suppliers, Abrex Plate Manufacture, Abrex Plate Distributors, Abrex Plate saler, Abrex Plate Stockist, Abrex Plate Bulk Distributors, Abrex Plate supplies, Abrex Plate exporters

|